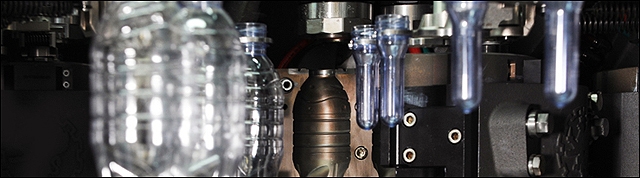

Sacmi is again confirming its status as the only supplier of systems and solutions for the beverage world to have developed its own technology for each of the key pieces of machinery in the process. The rotary stretch blow moulding machines of the SBF series form part of this range and are a highly reliable and efficient equipment for any customer wanting to mould its own bottles.

These are SBF technology’s strengths:

• Double cavity

• Rapid format change-over

• Integrated solutions upstream and downstream the line

The Sacmi SBF range of rotary stretch-blow moulding machines, featuring from 6 to 18 blow moulding stations, represents high-end equipment able to produce more than 48,000 bottles per hour in the standard half-liter format. The distinguishing characteristic of Sacmi SBF machines, and an important advantage too, is the possibility to install on each machine of the range a mould with 1 cavity for a large bottle (up to 3 Liters) or with 2 for a small one (up to 600 ml). and switch between them with the greatest ease and speed. In this way, it is possible to process more than 2,700 small bottles per hour per station, making full use of the moulding machine’s capacity and productive potential of any filling machine to which it might be connected.

The Sacmi SBF machine has also been designed to be integrated upstream of PAM, Sacmi’s exclusive compression preform production system.

Sacmi’s expertise is not confined just to machines and processes.

Today, Sacmi is the world’s only supplier capable of offering integrated CAP + PREFORM + BOTTLE

solutions tailor-made to meet the specific needs of the customer and the exact application.

The Sacmi test lab is fully equipped to develop these products. Pilot moulds and dedicated production

machines allows samples to be made quickly and then tested to assess their performance, mechanical

strength, thermal stability and sealing capacity as per internationally recognised test protocols.